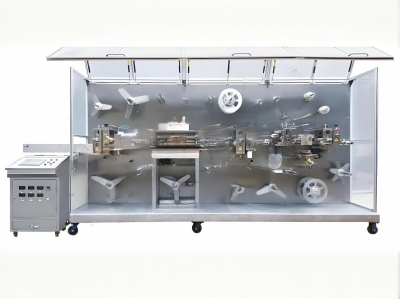

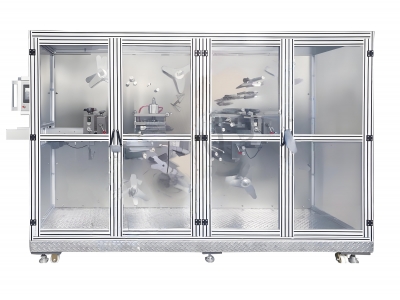

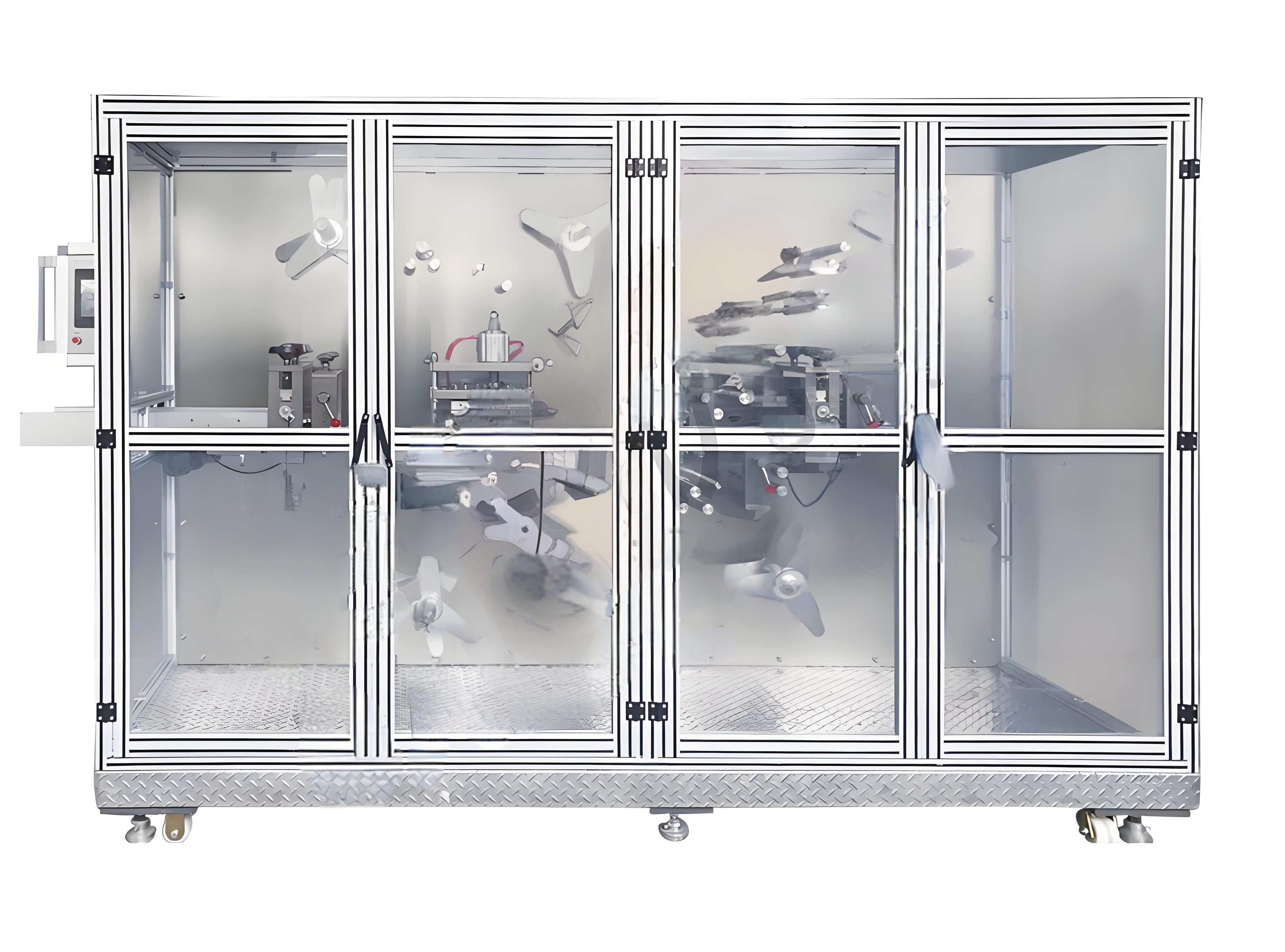

Fully Automatic IV Securement Dressing Packaging System

Why This Machine Stands Out

✔ Dual-Material Versatility - Process both transparent PU films (for IV dressings) and nonwoven fabrics (for general dressings)

✔ Pharmaceutical-Grade Sealing - Choose between mold-type (for complex shapes) or roller-type (for high-speed) sealing

✔ Military-Grade Precision - ±0.1mm positioning accuracy with advanced motion control

Breakthrough Technology

1. Intelligent Production Control

Next-gen motion controller outperforms traditional PLCs with:

→ 0.005mm repeat positioning accuracy

→ Self-correcting web guidance system

→ Predictive maintenance alerts

2. Complete Servo-Driven Process

8 precisely synchronized stations:

Adhesive substrate unwinding

PU film window cutting

Cotton core feeding & rotary die cutting

Mold/roller thermal sealing (switchable in 15min)

Sterile packaging with alignment control

3. Customizable for Your Needs

3 tension control modes:

Manual (for prototyping)

Constant tension (standard production)

Full servo (premium precision)

Special configurations available:

Top/bottom packaging alignment (±0.2mm)

Automatic web guiding for wrinkle-free sealing

Technical Specifications

| Parameter | Specification | Medical Industry Standard |

|---|---|---|

| Max Speed | 100 packs/min | 60-80 packs/min |

| Accuracy | ±0.1mm | ±0.3mm |

| Power | 13.5kW | 15-20kW |

| Tooling Change | <10 min | 20-30 min |

Certified Performance

◈ Validatable per FDA 21 CFR Part 820

◈ Material compliance: USP Class VI, ISO 10993-5

◈ CE marked electrical systems

Ready to Upgrade Your Production?

✅ Free production line assessment

✅ 12-month performance guarantee

✅ Dedicated engineering support