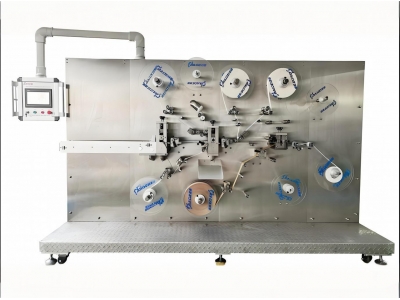

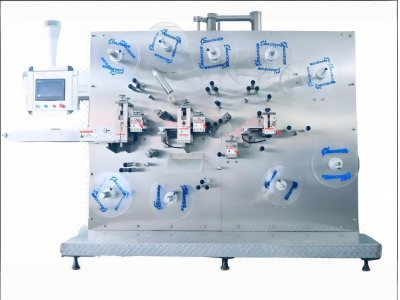

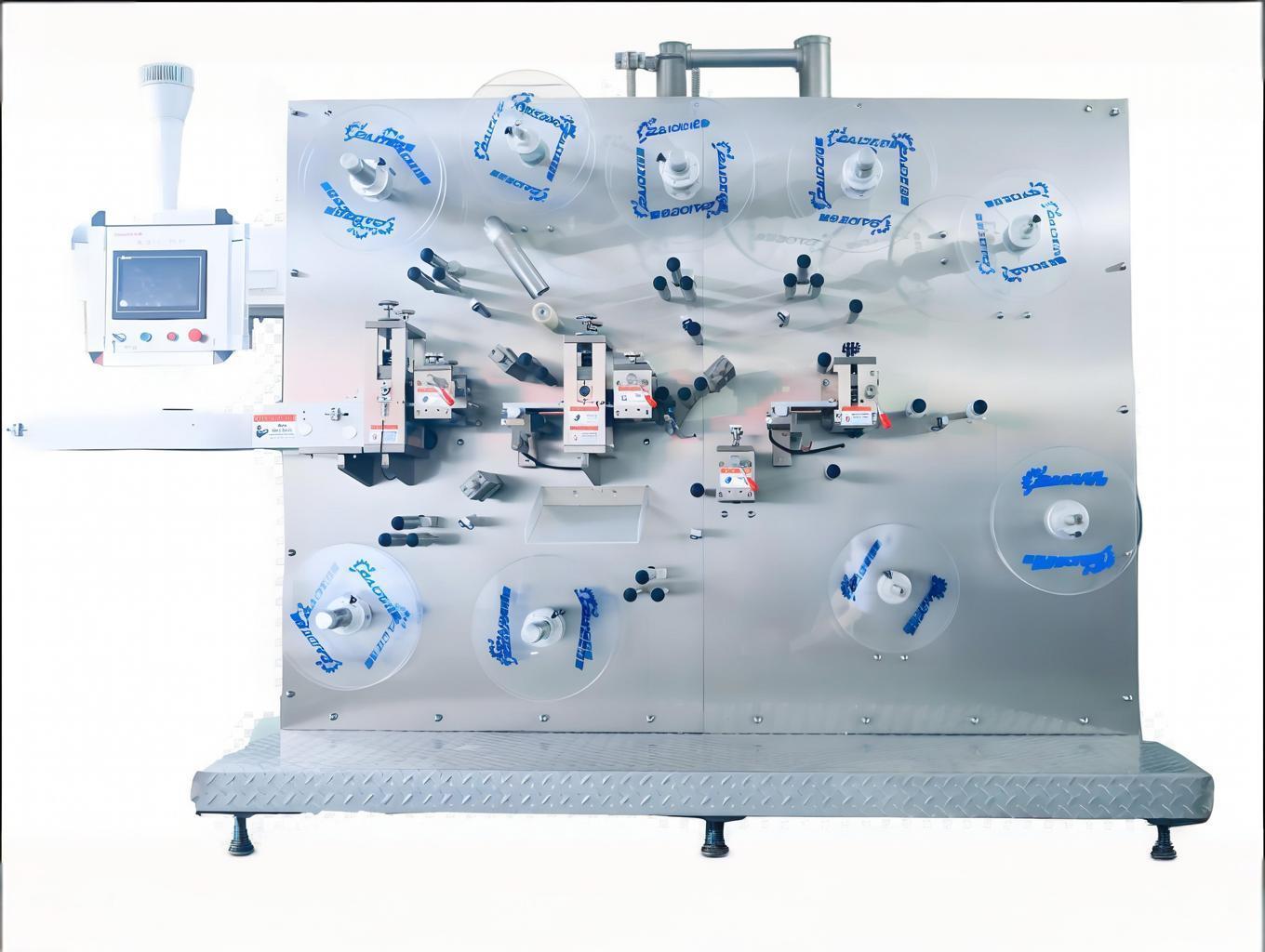

Fully Automatic High-Speed Band-Aid Production Machine

Product Overview

Zowinda's HX-1500 Band-Aid Machine redefines production standards with blistering 1500 packs/minute output while maintaining pharmaceutical-grade precision. Engineered for OEMs and contract manufacturers, this system delivers:

✔ Dual sealing technology - Hot seal for standard products/Cold seal for sensitive formulations

✔ Material versatility - Processes adhesive-coated nonwoven, cotton fabric, and transparent film

✔ Future-proof automation - IoT-ready with predictive maintenance alerts

Industry-Leading Performance:

→ 50% faster than conventional bandage machines

→ 30% lower energy consumption (7kW total power)

→ 15-minute quick changeover between product types

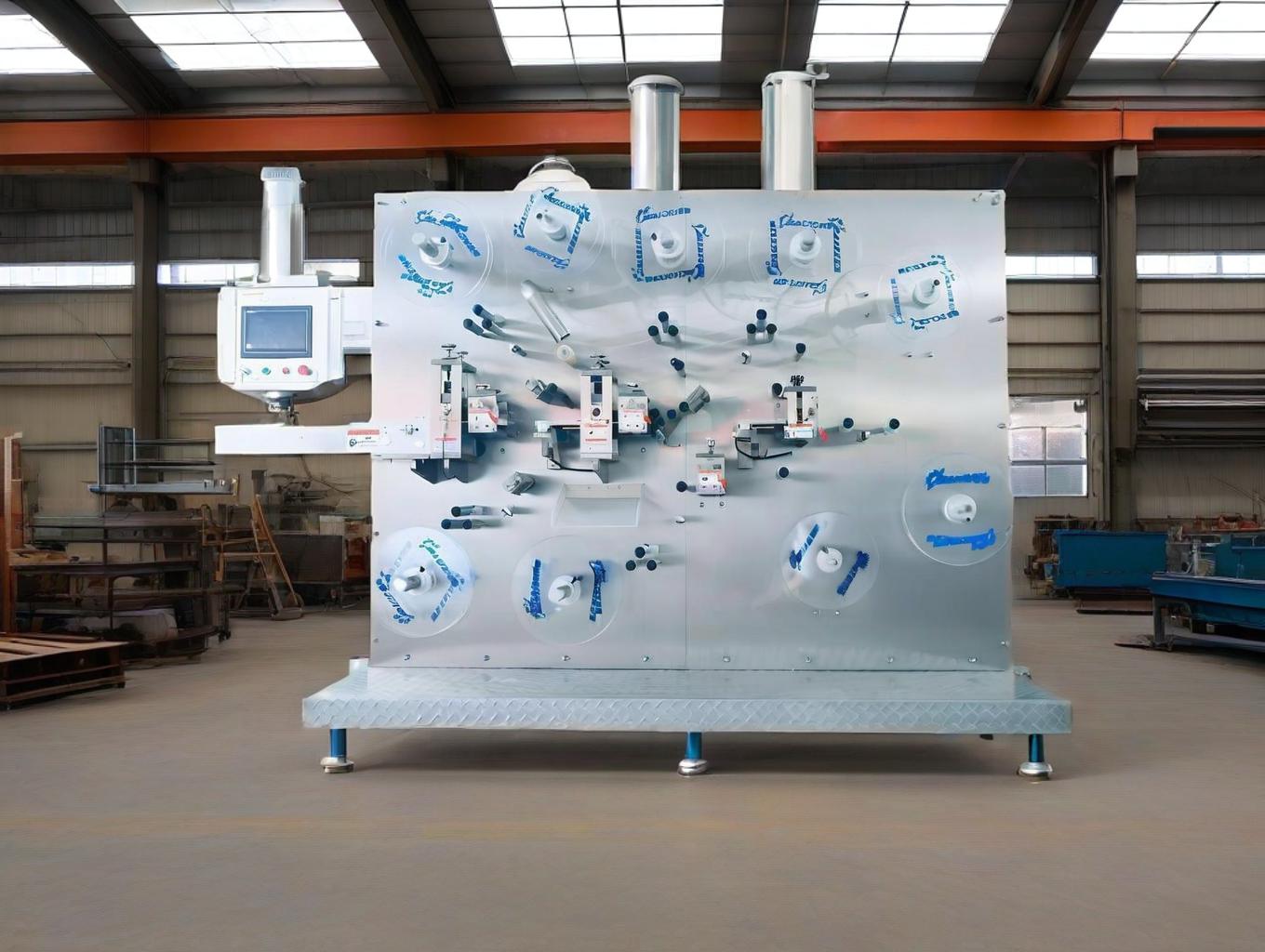

Technical Superiority

1. Intelligent Motion Control System

Advanced motion controller replaces traditional PLCs with:

→ 0.005mm repeat positioning accuracy

→ Self-learning tension compensation

→ Remote diagnostics via HMI

2. Complete Servo-Driven Production

6 perfectly synchronized stations:

Adhesive substrate unwinding (500mm max roll diameter)

Cotton core feeding & precision rotary cutting

Forming & final die cutting (±0.1mm tolerance)

Dual-mode sealing (switchable in <10 minutes)

Sterile packaging with optional alignment control

3. Customizable Production

Two tension control modes:

→ Constant tension for standard operation

→ Full servo for premium precision (±0.15mm)Special configurations available:

→ Top/bottom packaging alignment

→ Automatic web guiding system

Technical Specifications

| Parameter | Zowinda HX-1500 | Industry Standard |

|---|---|---|

| Max Speed | 1500 ppm | 800-1000 ppm |

| Accuracy | ±0.1mm | ±0.3mm |

| Power | 7kW | 10-12kW |

| Changeover | 15 min | 30+ min |

| Dimensions | 3600×1050×2150mm | Larger footprint |

Competitive Advantage Section

Zowinda HX-1500 vs. Industry Alternatives

| Feature | Zowinda HX-1500 | Competitor A | Competitor B |

|---|---|---|---|

| Max Speed | 1500 ppm | 1000 ppm | 800 ppm |

| Sealing Options | Hot & Cold | Hot Only | Cold Only |

| Material Changeover | 8 minutes | 20 minutes | 25 minutes |

| Accuracy | ±0.1mm | ±0.3mm | ±0.5mm |

| Smart Features | Predictive Maintenance Alerts | Basic PLC | None |

| Energy Efficiency | 7kW | 10kW | 12kW |

Key Differentiators:

Only machine offering both hot and cold sealing without tooling change

30% faster ROI (14 months vs industry average 20 months)

Future-ready IoT connectivity for Industry 4.0 integration

Clinical Validation Case Study

Project: Pediatric Bandage Production for EU Hospital Network

Challenge:

Needed to produce 12 SKUs of hypoallergenic bandages

Required cold sealing for sensitive skin formulations

Zero tolerance for adhesive bleed

Zowinda Solution:

Implemented quick-change cold seal modules

Added laser-guided edge detection system

Integrated 100% inline vision inspection

Results (9-month data):

▸ 99.98% defect-free production rate

▸ 45% faster SKU changeovers vs previous system

▸ Passed EN 13726-1:2002 adhesion tests

Updated Technical Specifications

New Available Options:

Cleanroom Package (ISO Class 7) +$22,000

Low-Migration Adhesive Module (for sensitive formulations) +$18,500

Multi-Language HMI (EN/DE/FR/ES) +$3,200

Trust-Building Elements

Expert Endorsement

"The ±0.1mm accuracy ensures perfect pad centering - critical for pediatric applications."

— Dr. Sarah Müller, Medical Device ConsultantLive Production Counter

"4,821,556 bandages produced this week on Zowinda machines"