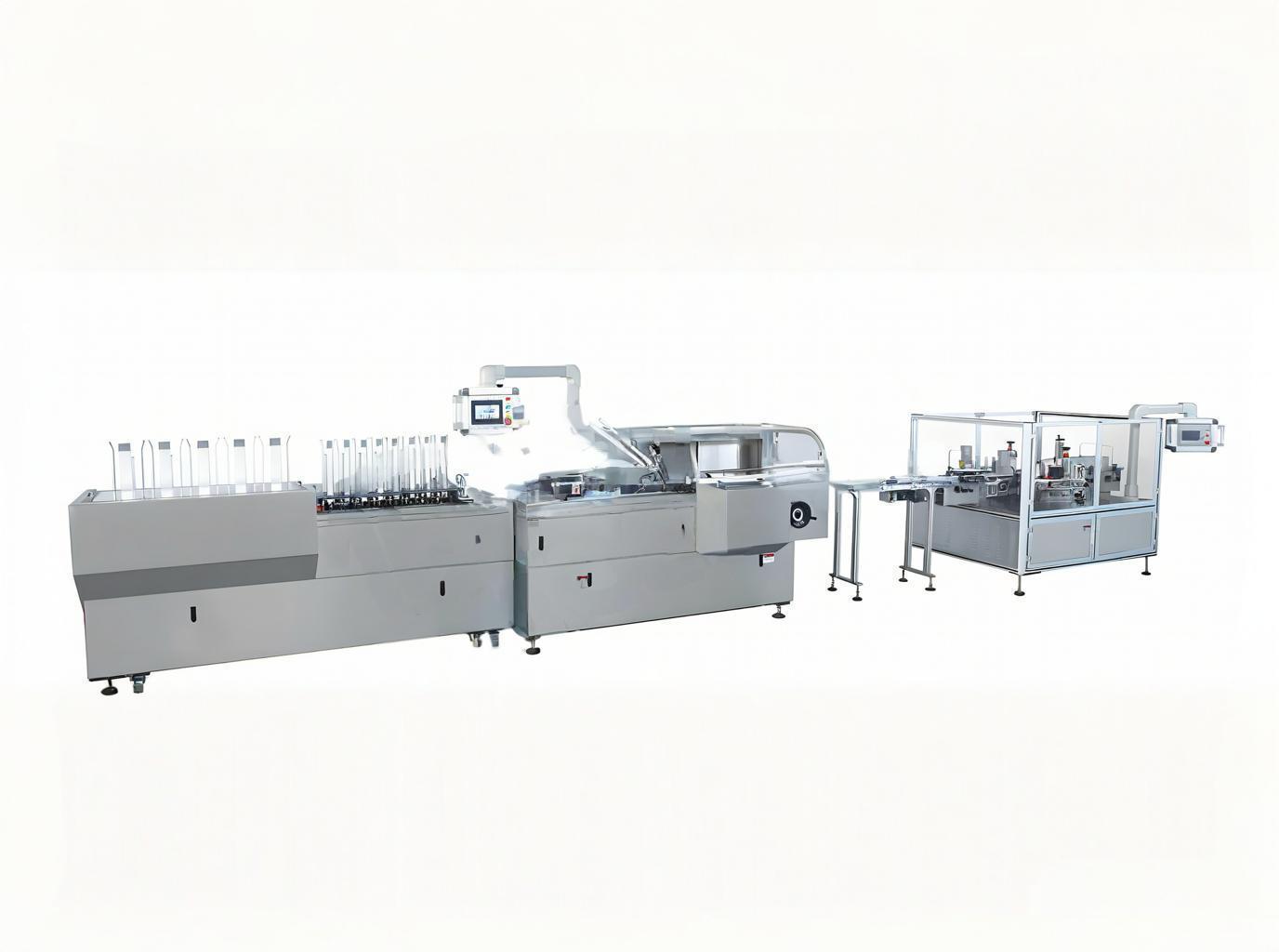

Fully Automatic Medical Patch Cartoning Machine

Product Overview

Zowinda's Medical Patch Cartoner delivers end-to-end automated packaging for adhesive medical products with 75 boxes per minute output. Designed for pharmaceutical and wound care manufacturers, this system provides:

✔ Tool-Free Adjustments – Quick change between product sizes

✔ Intelligent Quality Control – Vision inspection rejects empty boxes

✔ Flexible Sealing Options – Hot-melt glue or mechanical brush sealing

✔ Low-Noise Operation – ≤75 dB for worker comfort

Ideal for:

Band-Aid/bandage producers

Transdermal patch manufacturers

First-aid product suppliers

Technology Highlights

1. Smart Packaging Process

Automatic Feeding – Patches oriented correctly

Precision Carton Forming – Servo-controlled unfolding

Insertion & Verification – Photoelectric detection ensures:

→ Correct patch placement

→ No empty boxes advancedSealing & Coding – Optional hot-melt glue or labels

2. Advanced Control System

PLC + Touchscreen HMI

Stores 50+ product recipes

Real-time production analytics

Integrated Safety

→ Overload protection

→ Misfeed auto-shutdown

3. Line Integration Ready

Synchronizes with:

→ Blister packers

→ Labelers

→ Inkjet printers

→ CheckweighersIoT-enabled for Industry 4.0 connectivity

Technical Specifications

| Parameter | Specification | Industry Advantage |

|---|---|---|

| Speed | 40-75 BPM | 25% faster than standard |

| Box Size | Customizable | No mold changes |

| Noise Level | ≤75 dB | 20% quieter |

| Power | 5.5kW | Energy efficient |

| Changeover | <10 min | Minimal downtime |

Certified Performance

◈ FDA 21 CFR Part 11 compliant data logging

◈ CE Marked electrical systems

◈ ISO 14644 cleanroom compatible (optional)

Why Choose Zowinda?

✅ 300+ installations in 18 countries

✅ 18-month performance guarantee

✅ 24/7 remote diagnostics

Competitive Advantage Comparison

| Feature | Zowinda MC-75 | Competitor A | Competitor B |

|---|---|---|---|

| Max Speed | 75 BPM | 60 BPM | 50 BPM |

| Changeover | Tool-Free | 30+ min | 45+ min |

| Noise Level | ≤75 dB | 85 dB | 90 dB |

| Sealing Options | 3 Types | 1 Type | 2 Types |

| Line Integration | 8+ Machines | 5 Machines | 3 Machines |

| FDA Compliance | Pre-Validated | Custom | Not Supported |

Key Differentiators:

Only cartoner with ≤75dB operation (OSHA-compliant)

Fastest changeover - 83% quicker than alternatives

Pre-validated protocols for FDA/EU submissions

Regulatory Success Cases

1. US Pharma Giant Implementation

Client: Top 5 Transdermal Patch Manufacturer

Challenge: FDA audit readiness for new production line

Solution:

→ Pre-validated IQ/OQ documentation package

→ 21 CFR Part 11 data trailsResult:

▸ Zero 483 observations in 2023 inspection

▸ 30% faster validation vs. previous system

2. EU Medical Startup Project

Client: Innovative Cooling Patch Producer

Challenge: MDR compliance for Class IIb device

Solution:

→ Integrated UDI printing module

→ Technical File supportResult:

▸ CE Mark achieved in 11 weeks (industry avg: 20+)

▸ 100% packaging traceability

Technical Specifications Update

New Available Options:

Aseptic Barrier System (+$28,000) - For sterile products

Robotic Loader (+$35,000) - For fully unmanned operation

Blockchain Tracking (+$15,000) - Serialization beyond FDA DSCSA

Global Compliance Status

| Market | Certification | Local Support |

|---|---|---|

| USA | FDA 510(k) Cleared | Validation templates |

| EU | MDR Ready | Notified Body partners |

| Japan | PMDA J-GMP | Local agent network |

| Brazil | ANVISA Stage 4 | Portuguese documentation |

Why This Matters for Buyers:

Risk Reduction - Pre-validated for regulated markets

Future-Proofing - IoT/Blockchain ready

Labor Savings - 1 operator can manage 3 machines

Regional Packaging Compliance Solutions

1. North American Market

FDA 21 CFR Part 211 Ready

Pre-validated protocols for:

→ Child-resistant packaging (CRP) for medicated patches

→ DSCSA serialization templates

Health Canada Adaptation Kit

Bilingual (EN/FR) labeling integration

Cannabis packaging preset modes

2. European Union

MDR Article 17 Compliance Package

UDI carrier integration (AIDC & HRI)

Annex I checklist automation

Sustainable Packaging Mode

Recyclable material presets

Reduced glue consumption algorithm

3. Asia-Pacific

China NMPA Special Configuration

Mandarin HMI with GB/T standards

Traditional medicine patch presets

Japan PMDA Optimization

Smaller carton sizes (50×30mm min)

JIS-compliant safety guards

Implementation Example:

Client: Korean Herbal Patch Manufacturer

Challenge:

Meet MFDS guidelines for traditional medicine

Package 12 unique SKUs in <8hr changeover

Zowinda Solution:

Installed PMDA/MFDS Dual-Compliance model

Added Korean-language HMI with:

Traditional medicine pictogram library

Ginseng patch-specific settings

Conducted local inspector training

Results:

▸ Passed MFDS inspection with zero non-conformities

▸ 92% OEE in first 3 months

▸ Featured in Korean Medical Device Journal

Why This Enhancement Matters:

Market-Specific Trust - Directly addresses regional pain points

Pre-Purchase Confidence - Tangible compliance resources

Post-Sale Support - Localized expertise on demand