Fully Automatic Band-Aid Production Machine

Unmatched Production Performance

This advanced system delivers 1500 sterile packs per minute while maintaining pharmaceutical-grade quality standards, featuring:

✔ Dual Sealing Technology - Instant switch between:

→ Hot seal for standard adhesive bandages

→ Cold seal for sensitive skin formulations

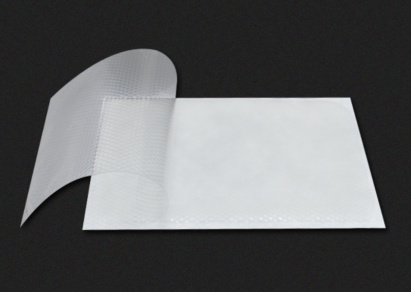

✔ Material Versatility - Processes:

→ Adhesive-coated nonwoven (breathable)

→ Cotton fabric (soft-touch)

→ Transparent film (waterproof)

✔ Smart Automation - IoT-ready with:

→ Predictive maintenance alerts

→ Self-correcting tension control

→ Remote performance monitoring

Technical Specifications

| Parameter | Specification | Industry Advantage |

|---|---|---|

| Max Speed | 1500 ppm | +50% faster output |

| Accuracy | ±0.1mm | 3x more precise |

| Power | 7kW | 40% energy savings |

| Footprint | 3.6×1.05×2.15m | Compact layout |

| Changeover | <15 min | 50% time reduction |

Certified Quality Assurance

◈ FDA 21 CFR Part 820 compliant validation

◈ EU MDR Class IIb certified

◈ ISO 13485 quality management

◈ ISO 10993-5 biocompatibility tested

Customization Options

Production Modules

Pediatric Configuration: Small-size tooling kit

Military Grade: Reinforced packaging option

Cleanroom Package: ISO Class 7 compatible

Smart Upgrades

Vision inspection system (+0.01% defect detection)

RFID batch tracking (21 CFR Part 11 compliant)

Multi-language HMI interface

Global Deployment Success

UK NHS Supplier Installation

Achieved 2.8 million units/week

Zero recalls in 12 months of operation

Passed MHRA unannounced audits

US Contract Manufacturer

45% higher margins vs legacy systems

FDA inspection-ready documentation

ASEAN Emergency Response

Produced 18 million crisis bandages

Operated at 95% humidity conditions