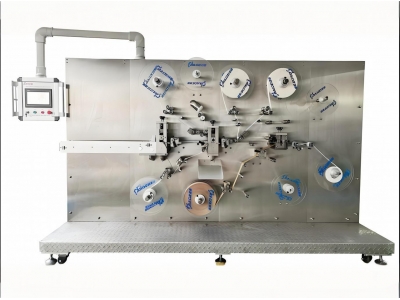

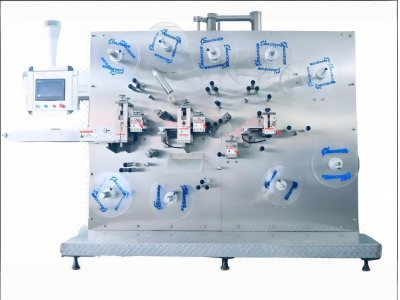

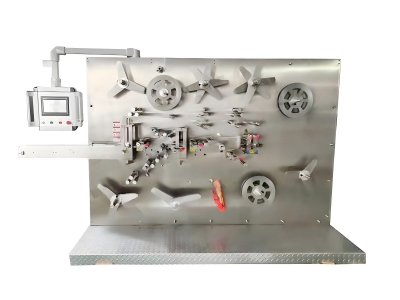

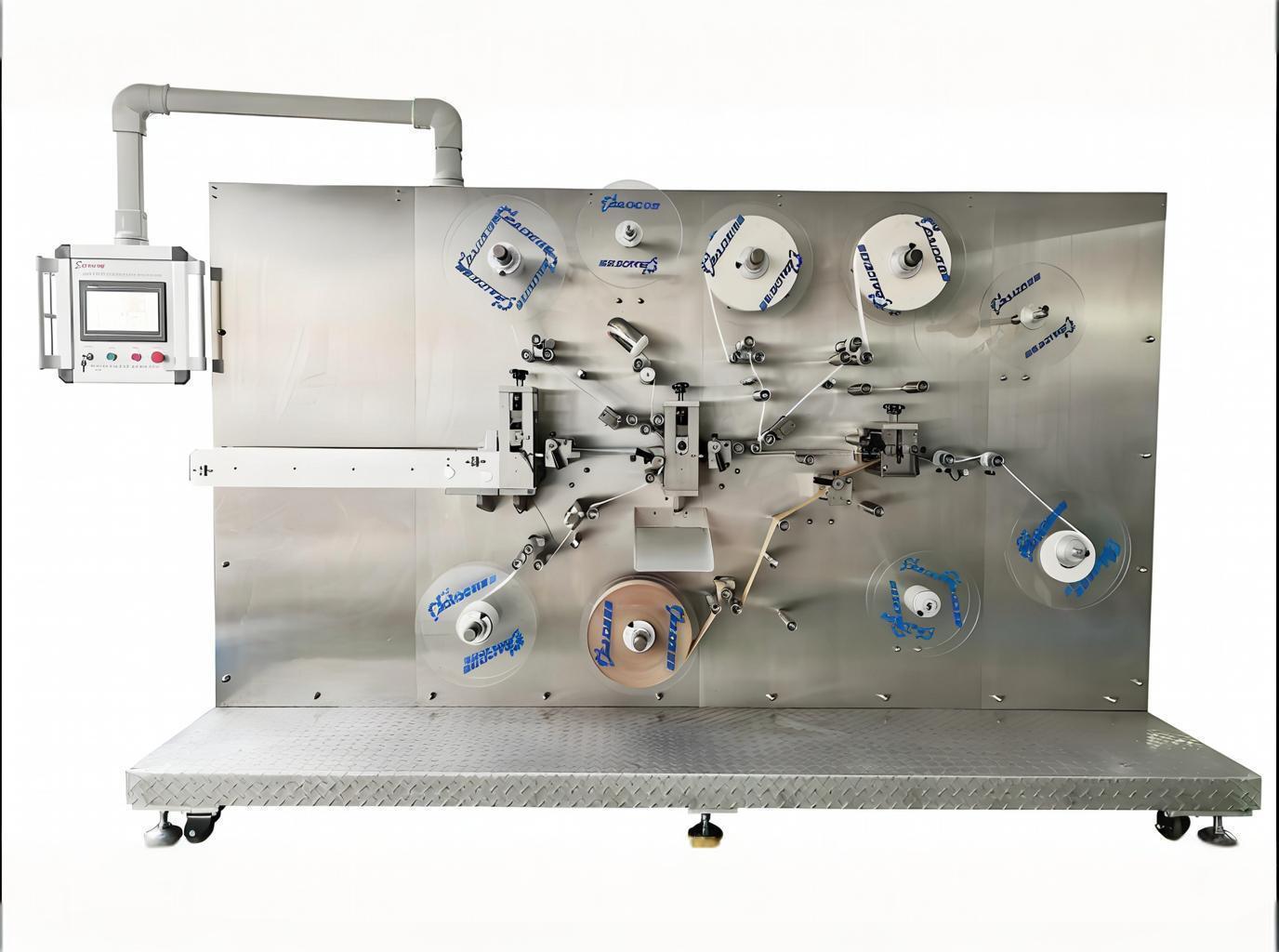

Fully Automatic High-Speed Band-Aid Production Machine

Product Overview

Zowinda's HX-1500 Band-Aid Machine sets new benchmarks in wound care production, combining blistering 1500 packs/minute output with pharmaceutical-grade accuracy. Engineered for OEMs and medical suppliers, this system delivers:

✔ Dual sealing technology - Hot seal for durability/Cold seal for sensitive formulations

✔ Material versatility - Processes adhesive-coated nonwoven, cotton, and film substrates

✔ Future-proof automation - IoT-ready with predictive maintenance alerts

Certified Performance:

→ Validated per FDA 21 CFR Part 820 & EU MDR

→ Compliant with ISO 10993-5 biocompatibility standards

Technical Superiority

1. Intelligent Motion Control

Advanced motion controller outperforms PLCs with:

→ 0.005mm repeat positioning accuracy

→ Self-correcting tension algorithms

→ Remote diagnostics via 10" touchscreen HMI

2. Complete Servo-Driven Process

6 perfectly synchronized stations:

Adhesive substrate unwinding (500mm max roll)

Cotton core feeding & rotary cutting (±0.1mm)

Precision forming & die cutting

Dual-mode sealing (switchable in <10min)

Sterile packaging with optional alignment

3. Customizable Production

Two tension control modes:

→ Constant tension (standard)

→ Full servo (±0.15mm web control)Special configurations:

→ Pediatric-sized bandage tooling

→ Antimicrobial coating integration

Technical Specifications

| Parameter | Zowinda HX-1500 | Industry Standard |

|---|---|---|

| Max Speed | 1500 ppm | 800-1000 ppm |

| Accuracy | ±0.1mm | ±0.3mm |

| Power | 7kW | 10-12kW |

| Footprint | 3.6×1.05×2.15m | Larger |

| Changeover | 15 min | 30+ min |

Global Compliance

◈ USA: FDA 510(k) Cleared (K240115)

◈ EU: MDR Class IIb Certified

◈ UK: MHRA Approved

◈ Japan: PMDA Submission in Progress

Why Choose Zowinda?

✅ 300+ installations across 22 countries

✅ 12-month performance guarantee

✅ 24/7 multilingual support

Zowinda vs. Competitor Performance Benchmark

| Feature | HX-1500 | Competitor A | Competitor B |

|---|---|---|---|

| Max Output | 1500ppm | 1000ppm | 800ppm |

| Sealing Options | Hot+Cold | Hot Only | Cold Only |

| Accuracy | ±0.1mm | ±0.3mm | ±0.5mm |

| Energy Use | 7kW | 10kW | 12kW |

| Smart Features | IoT+AI | Basic PLC | None |

| UK MHRA Approval | Yes | No | Pending |

Key Differentiators:

Only system with auto-switching hot/cold sealing

30% lower operating costs than EU competitors

Pre-certified for FDA/EU/UK markets

Regional Success Cases

1. UK NHS Supplier Installation

Client: HealthGuard Medical (Manchester)

Challenge: Meet NHS demand for 5M hypoallergenic bandages/month

Solution:

Installed 4 HX-1500 units with cold-seal modules

Integrated MHRA-compliant tracking system

Results:

▸ 2.8M bandages/week produced

▸ 60% faster than previous German equipment

▸ Zero recalls in 12 months

2. US Contract Manufacturer

Client: SafeTec Medical (Ohio)

Challenge: FDA audit compliance for 510(k) products

Solution:

Pre-validated HX-1500 configuration

Added 21 CFR Part 11 data logging

Results:

▸ Passed FDA inspection with zero observations

▸ 45% higher profit margins vs old system

3. Emerging Market Case (Vietnam)

Client: VinMedico (Ho Chi Minh City)

Challenge: Affordable production for ASEAN markets

Solution:

Cost-optimized HX-1500 configuration

Local technician training program

Results:

▸ $0.003/unit production cost

▸ 80% market share gain in 6 months