Company dynamics

The function of plasma processor

Plasma can be used in many different cases whenever you would like to better adhere materials together or to change a surface property to suit your needs. With this trend-setting technology it is possible to modify virtually any surface.

Plasma technology offers several versatile applications, for example:

Cleaning surfaces of any residues, oils, or contamination

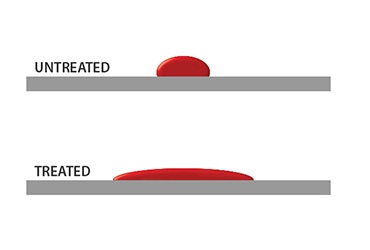

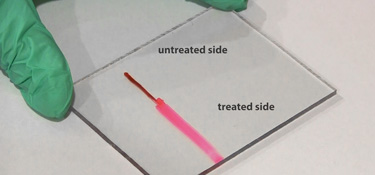

Activation of various materials before gluing, painting, etc.

Etching and partial removal of surfaces

Coating of parts with several possible types of layers (PTFE-like, protective barriers, hydrophobic, hydrophilic, friction-reducing, etc.)

Plasma technology is establishing itself in all areas of industry, and new applications are constantly evolving.

Plasma Technology - Convincing Advantages

Compared to other methods, like flame treating or using chemicals to treat a surface, plasma technology exhibits many important advantages:

Many surface properties can be obtained exclusively with this procedure

Can be used in online production or operated independently

nvironmentally friendly process

Regardless of geometry you are able to treat powder, small parts, discs, fleece, textiles, tubing, bottles, circuit boards, etc.

Fabricated parts will not be mechanically changed

Heating of the parts is minimal

Operating costs are very low

Extremely safe to operate

Process is extremely energy efficient

Categories

News

Contact Us

Contact: Plasma Machine

Phone: +86-18665474518

Tel: + 86-18665474518

Skype: michaeldzc

E-mail: [email protected]

Add: Xixiang Street, Bao'an District, Shenzhen, Guangdong, China