Plasma Treatment Machine

Plasma Surface Treatment Machine

Plasma Surface Treatment Machine

OVERVIEW

Plasma treaters produce plasma surface treatment to promote the adhesion of inks, adhesives, coatings, sealants & paints. It could also clean the surface with ideal neat and tidy areas. The manufacturers or factories integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, functionalizes surfaces to activate bonding areas by increasing wettability and surface energy.

This plasma surface treatment could make the surface of the products easier to make the printing, painting, adding glue, cleaning, welding etc..

Winda Plasma Surface Treatment Machines provide industrial manufacturers in the assembly, printing & decorating industries with repeatable adhesion process control. In many cases plasma surface treatment eliminates the need for hazardous primers and inefficient manual surface preparations.

MAIN FEATURES

1. The surface treatment is fast and reliable.

2. The well-distributed plasma beam ensures the even and stable surface treatment.

3. It is low cost and environmental pre-process for the products.

4. It could purge the material surface chemicals, organic contamination, and it could clean the dust on it too. 5. The treatment is better than water clean or CO2 clean system because no additional material cost. And compare with sand blasting, it could process the whole material structure, not only the projecting forward part.

5. The treatment is better than water clean or CO2 clean system because no additional material cost. And compare with sand blasting, it could process the whole material structure, not only the projecting forward part.

6. The plasma treatment could be integrated with the product production line, no need pre-process.

7. Reliable system: the machine could self-check after startup, it monitors all the working process and parameters. It has the warnings and protection functions.

8. The machine interface is easy to adjust and set the parameters and check the system. The machine could be work in alone mode or in-line mode. It has the RS485 communication port, so the machine could be remotely controlled.

9. The treatment energy density could be adjustable according to the material speed.

10. The plasma machine nozzle could be customized according to the products or working environments.

Application Examples

1. Printings: Getting inks to successfully bond to a wide range of plastics is an industrial challenge across many industries. Plasma and flame surface treaters have proved invaluable at preparing surfaces for ink adhesion in the decorating, packaging, identification, and marking applications.

When inks do not bond with surfaces it is often because the surface has inherently low surface energy, surface contamination and additives which have risen to its surface. In-line surface treating is performed immediately prior to printing and creates a high energy surface, cleaned of contaminates and functionalized with increased bonding sites for adhesion.

For examples: cards pre-processing for DOD, UV, Inkjet Printing. After plasma treatment, the ink will be stick more firmly and clearly on the cards.

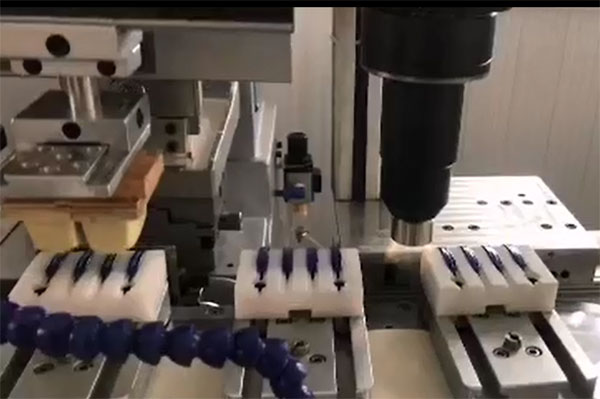

Plasma is applied on DOD/UV Printing

Plasma is applied on ceramics pre-process before printing

2. Automotive: enable light weighting, & improve surface adhesion with atmospheric plasma & flame surface treatment.

Treating surfaces prior to gluing, painting, coating and printing increases surface energy and promotes superior bonding.

Plasma & flame treatment are effective on glass, metals, composites and polymer materials such as PE, PP, TPO, POM, PUR, ABS, ASA, PA, Nylon, PC, PET and PTFE.

Flame treating is useful for automotive applications where large areas will be treated prior to painting, decorating or adhesive bonding. Plastic bumpers, dashboards, consoles, and glove boxes are very receptive to treatment.

3. Electrical potting:

To protect electronics from shock, vibration, and environmental elements, including liquids and caustic substances, manufacturers will often use a potting compound in an electrical housing. Solid or gelatinous compounds such as thermosetting plastics or silicone rubber gels encapsulates the electronics for added protection.

In many cases the housings are made from a nonporous low surface energy plastic such as ABS, Polyamide, or other thermoset plastics. Plasma and flame surface treaters pretreat the interior of the housings to remove surface contaminants, micro etch the surface and increase surface energy to enable adhesion of the potting compound to the enclosure.

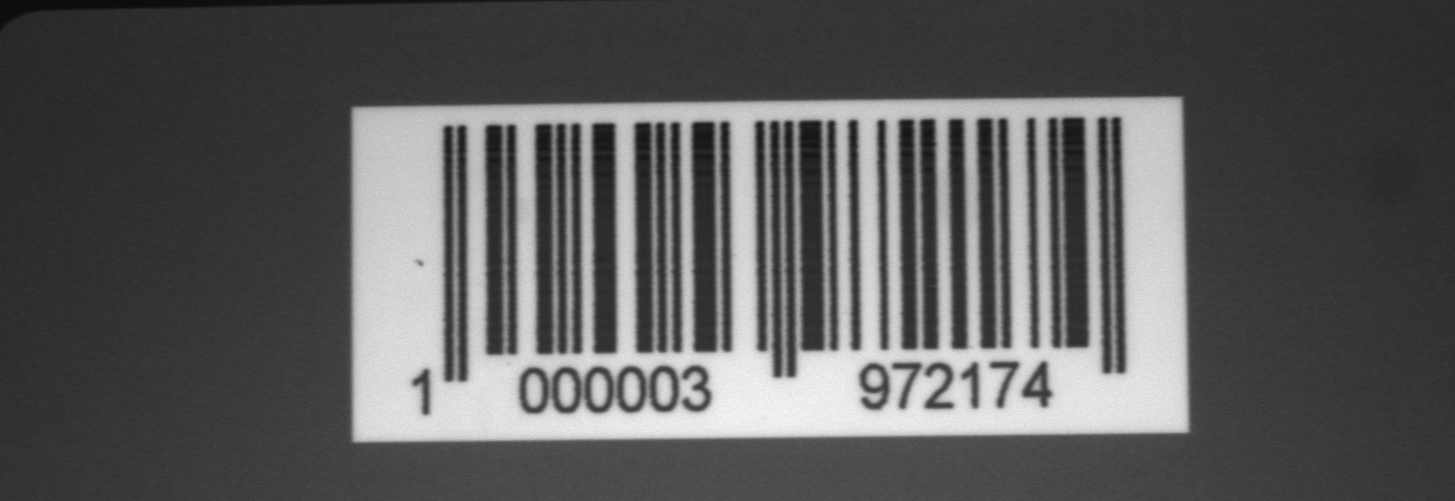

4. Wire & cables Manufacturers: Atmospheric plasma treaters are enabling manufactures to switch to ink jet printing from traditional marking methods such as hot stamping and print wheels. Economical ink jet printing is a non-contact printing process which supports high line speeds & fast changeovers. Changes to wire marking content are handled electronically and can be database driven.

Materials with low surface energy, including PE, PVC, PP, PTFE, XLPE, ETFE, FEP, EPDM, Silicone and more have difficulty bonding with inks. Plasma treatment activates these surfaces to improve wettability and bonding properties. This process creates indelible printing providing excellent abrasion and smudge resistance.

SPECIFICATIONS

MODEL | WDPL1000 |

Process Width | 1mm to 80mm |

Power Input | AC 220/230V, 50/60Hz |

Working Frequency | 18 to 60 KHz |

Working Voltage | 4 to 7 KV |

Air Pressure Input | 0.3 to 1 MPa |

Working Air Pressure | 0.05 to 0.5 MPa |

Working Power Output | 300 to 1200 W, it is adjustable according to the product |

Power Consumption | ≤1100 W |

Dimensions | 128*445*370 mm (main frame) |

Weight | 18Kg |

Categories

News

Contact Us

Contact: Plasma Machine

Phone: +86-18665474518

Tel: + 86-18665474518

Skype: michaeldzc

E-mail: [email protected]

Add: Xixiang Street, Bao'an District, Shenzhen, Guangdong, China