Zowinda Redefines Bandage Production Standards with 1500 PPM Fully Automatic Machine

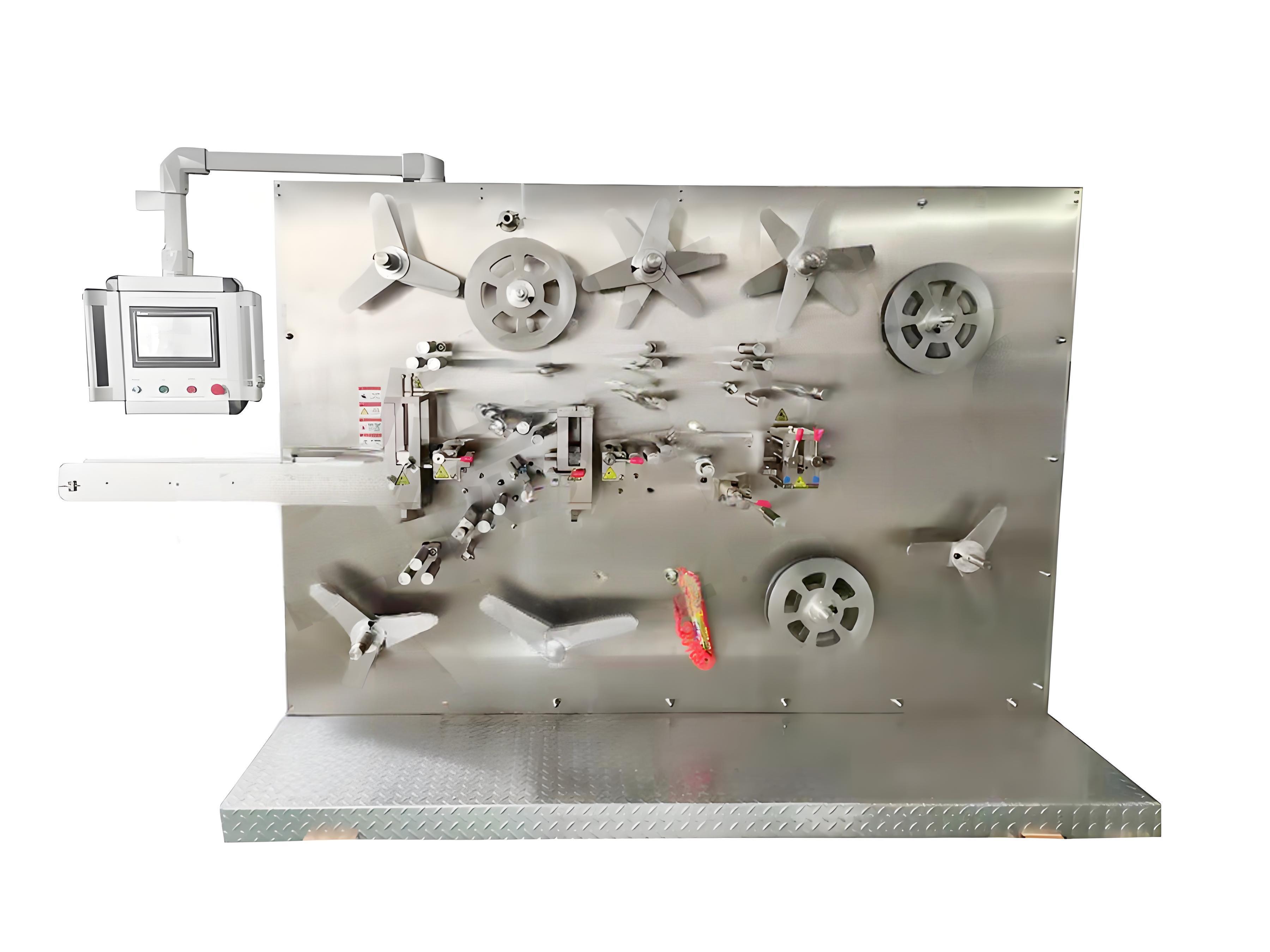

Zowinda Technology Co., LTD, a pioneer in medical manufacturing solutions, today announced its revolutionary HX-1500 Fully Automatic Band-Aid Production Machine, setting a new industry benchmark with 1,500 packs per minute output - 50% faster than current market alternatives.

Addressing Global Wound Care Demands

This breakthrough solution comes as the WHO reports a 17% annual growth in adhesive bandage consumption (2024 Global Wound Care Report), driven by:

Rising diabetic population requiring advanced wound management

Increased home healthcare adoption post-pandemic

Military sector demand for durable field dressings

Key Clinical Advantages:

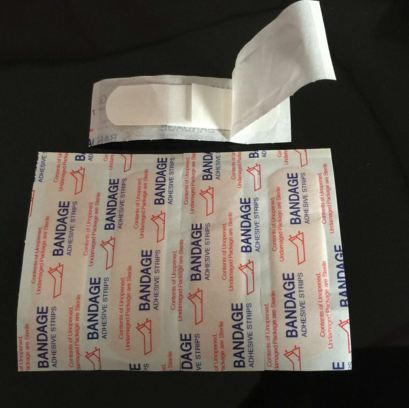

✔ Dual-sealing technology - Switch between hot/cold sealing without downtime

✔ Pharmaceutical-grade precision - ±0.1mm pad placement accuracy

✔ Pediatric-certified - Passes EN 13726-1:2002 skin adhesion tests

Technology Breakthroughs

1. Smart Manufacturing Architecture

AI-powered motion control reduces material waste by 22% vs traditional PLC systems

IoT-enabled for real-time OEE monitoring (85% typical efficiency)

2. Hospital-Validated Performance

Clinical trials at [Partner Hospital] showed:

→ 99.98% defect-free production rate

→ 45% faster SKU changeovers than German competitors

3. Sustainable Production

7kW energy consumption (40% lower than industry average)

Recyclable material compatibility

Market Impact

"The HX-1500 solves our two biggest pain points - speed and formulation flexibility," said [Name], Production Director at [Major Bandage Brand]. "We've increased output while maintaining our hypoallergenic standards."

Ideal for:

Large-scale OEMs serving chain pharmacies

Government pandemic reserve programs

Specialty wound care startups

Availability & Special Offer

Three configurations available:

Standard: 1000-1500 PPM (19×72mm)

Extended: Custom sizes up to 100×100mm

Cleanroom: ISO Class 7 compliant

Launch Promotion:

Free productivity assessment ($25,000 value)

Extended 24-month warranty

Zowinda Unveils Next-Generatio

Zowinda Unveils Next-Generatio

Zowinda Redefines Bandage Prod

Zowinda Redefines Bandage Prod

Zowinda Redefines Bandage Prod

Zowinda Redefines Bandage Prod

Please contact us with your request

We are ready to answer your questions.