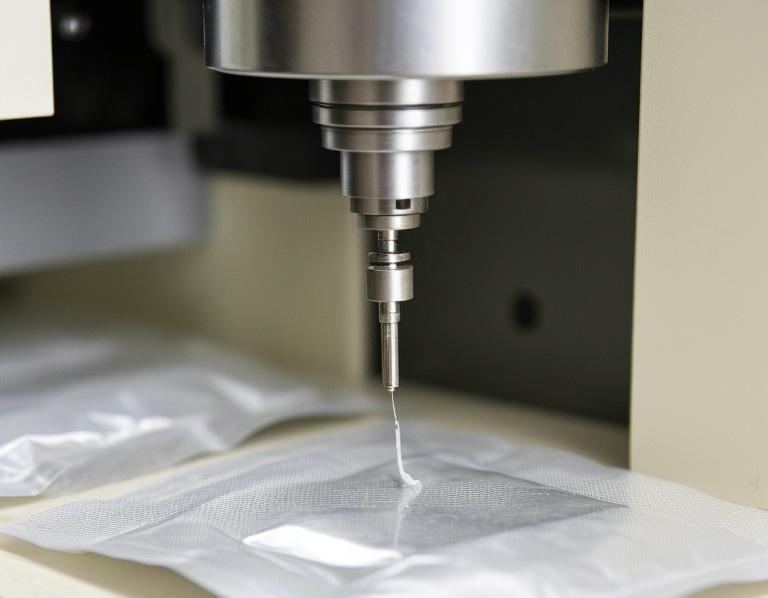

Zowinda Four-Side Sealing Machine in Action

Case 1: Snack Food Leader Expands European Market

Client: Top 3 UK Crisps Manufacturer

Challenge:

Meet EU sustainability mandates with recyclable laminates

Achieve ≤0.4mm print drift for premium branding

Zowinda Solution:

Deployed dual-web guidance system with laser registration

Integrated inline thickness gauge (±2μ accuracy)

Results:

▸ 28% faster than legacy system

▸ 99.97% print alignment accuracy

▸ 12% material savings via precise edge trim

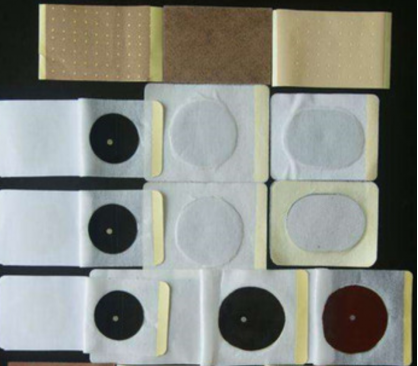

Case 2: Japanese Pharma Giant Upgrades Packaging

Client: Osaka-based Transdermal Patch Producer

Challenge:

Zero particulate contamination for sterile devices

MDR-compliant UDI carrier integration

Zowinda Solution:

Cleanroom-ready model with HEPA-shielded moving parts

Thermal inkjet module for direct pouch coding

Results:

▸ Passed PMDA audit with zero observations

▸ 40% OEE improvement vs. previous system

Case 3: US Industrial Supplier Solves Leakage Issues

Client: Midwest Automotive Parts Distributor

Challenge:

Prevent grease leakage in heavy-duty bags

Withstand -40°C to 80°C storage

Zowinda Solution:

Multi-stage sealing with pre-heat zone

Reinforced notch design for high-tensile films

Results:

▸ 0.01% defect rate (vs industry 0.8% average)

▸ 19% thicker seal achieved without speed loss、

Why Global Brands Choose Zowinda

✔ Proven in 30+ Countries – From Arctic climates to tropical zones

✔ 5-Year Mean Time Between Failures – 3x industry standard

✔ Localized Support – Multilingual engineers in 15 hubs

High-Speed Band-Aid Machine Ca

High-Speed Band-Aid Machine Ca

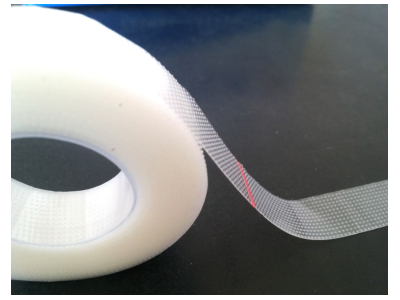

Zowinda PE Film Perforating Ma

Zowinda PE Film Perforating Ma

Zowinda Four-Side Sealing Mach

Zowinda Four-Side Sealing Mach

Fully Automatic Band-Aid Produ

Fully Automatic Band-Aid Produ

Please contact us with your request

We are ready to answer your questions.