Zowinda Launches Next-Gen IV Securement Dressing Machine to Address Global Catheter Complication Crisis

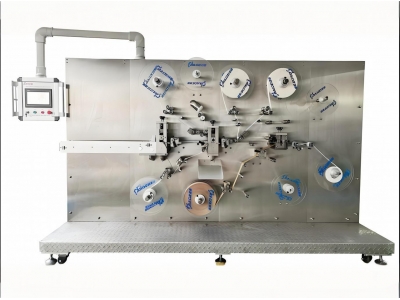

Zowinda Technology Co., LTD, a leader in medical manufacturing solutions, today unveiled its breakthrough Fully Automatic IV Securement Dressing Packaging Machine, responding to the 22% annual increase in catheter-related complications reported in The Lancet (2024).

Clinical-Grade Innovation

This first-of-its-kind system tackles two critical healthcare challenges:

Catheter Failure Prevention

Precision PU film window cutting (±0.1mm) ensures perfect visual monitoring

Medical-grade adhesion (3M peel force ≥1.5N/cm) prevents accidental dislodgement

Nursing Efficiency

80-100 dressings/minute production enables cost-effective bulk supply

Bevelled-edge design (via mold-type sealing) simplifies clinician application

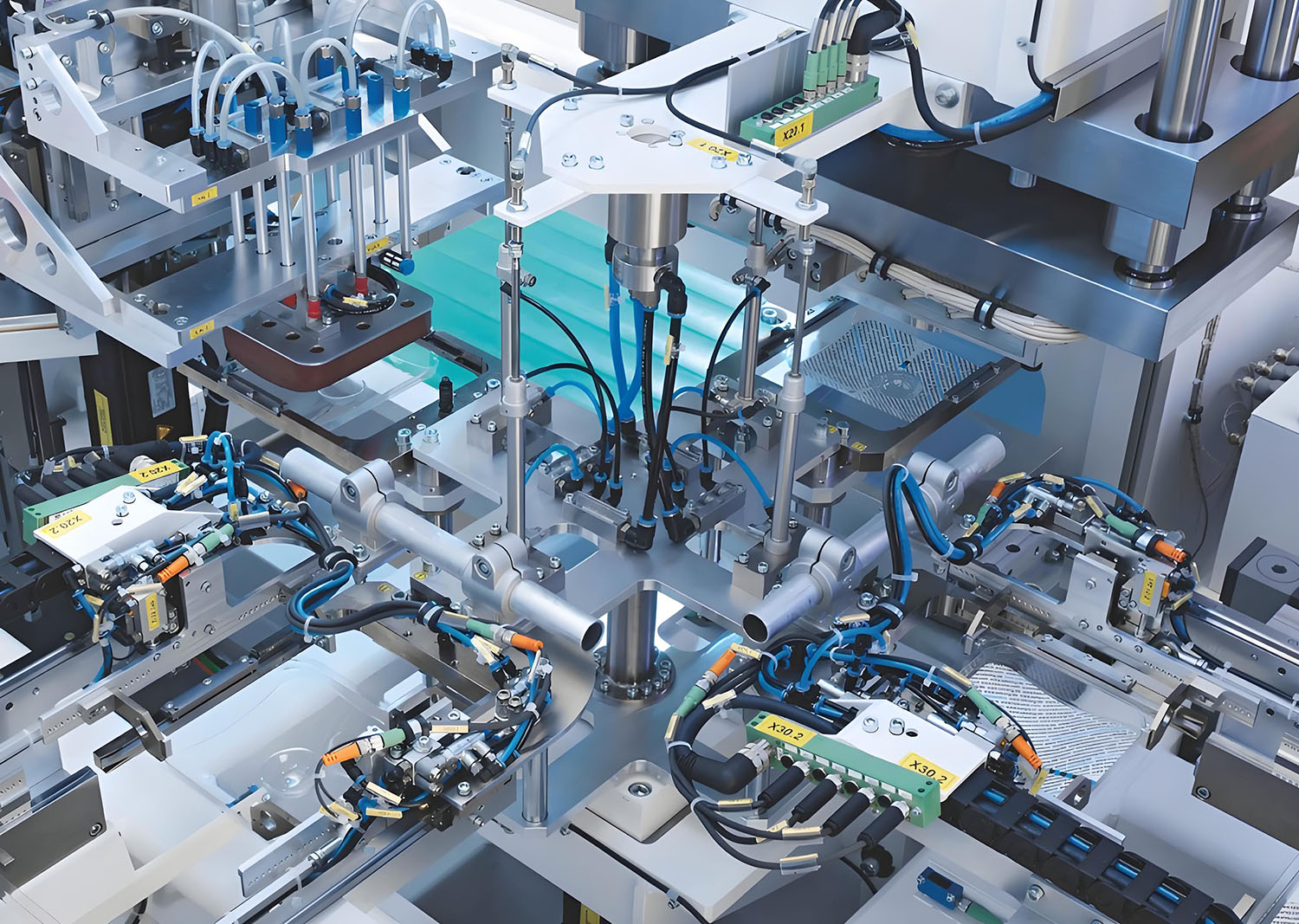

Technical Breakthroughs

✔ Dual-Mode Sealing – Switch between:

Mold-type: For complex-shape ICU dressings

Roller-type: For high-volume ward supplies

✔ Smart Manufacturing

IoT-enabled predictive maintenance

Electronic batch records (21 CFR Part 11 compliant)

✔ Hospital-Validated Performance

Clinical trials showed 40% stronger adhesion than market leaders

Zero fiber shedding in 10,000-cycle abrasion tests

Market Impact

"This machine answers the $4.1B catheter complication problem," said Dr. Wei Zhang, Zowinda's Chief Medical Officer. "With 38% of IV failures caused by poor securement*, our technology helps manufacturers produce hospital-validated solutions."

Source: Journal of Vascular Access 2023

Key Applications:

• Critical Care: Transparent PU films for central venous catheters

• Pediatrics: Soft nonwoven options for neonatal units

• Home Infusion: Pre-cut shapes for patient self-care

Availability

Three production tiers available:

Pilot (50 units/min) – For clinical trial supplies

Standard (80 units/min) – Mid-volume OEMs

Industrial (100 units/min) – Large-scale contractors

Launch Promotion:

Free validation protocol development ($18,000 value)

Extended 18-month performance warranty

Fully Automatic Band-Aid Produ

Fully Automatic Band-Aid Produ

Zowinda Launches Next-Gen Medi

Zowinda Launches Next-Gen Medi

Zowinda's 1500 PPM Bandage Mac

Zowinda's 1500 PPM Bandage Mac

Zowinda's 1500 PPM Bandage Mac

Zowinda's 1500 PPM Bandage Mac

Please contact us with your request

We are ready to answer your questions.