Zowinda Launches Fully Automated Silicone Gel Foam Dressing Production Line

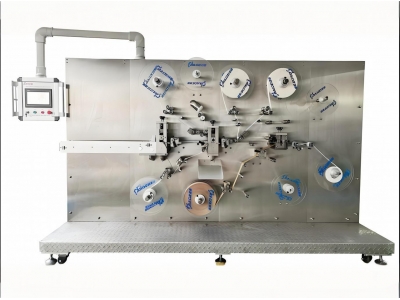

Zowinda Technology, a leading manufacturer of advanced medical equipment, has unveiled its next-generation Silicone Gel Foam Dressing Production Line, setting a new standard for efficiency and precision in wound care manufacturing.

Revolutionizing Foam Dressing Production

The fully automated system addresses critical industry challenges with breakthrough features:

Pharmaceutical-Grade Precision

Closed-loop control maintains ±2% thickness tolerance for foam matrices

Adjustable pore sizing (20-200μm) for customized wound exudate management

Flexible Manufacturing

Rapid switch between silicone/hydrogel/acrylic adhesives (<15min changeover)

Produces dressings meeting ISO 10993-5 and USP Class VI standards

Sterility Assurance

Integrated EO gas sterilization module

ISO Class 7 cleanroom-compatible design

Technical Highlights

▶ 50% Faster Production vs conventional systems (60 sterile packs/minute)

▶ Patented Coating Technology for gradient adhesive application

▶ IoT-Ready Architecture with predictive maintenance alerts

Market Implications

"This system answers the growing demand for advanced silicone foam dressings," said Dr. [Name], Chief Technology Officer at Zowinda. "Hospitals need products that combine high absorbency with gentle removal, and our equipment enables manufacturers to deliver this at scale."

The technology is particularly suited for:

• Chronic wound care: Optimized MVTR for diabetic ulcers

• Burn treatment: Customizable non-adherent layers

• Post-surgical use: Thin-film formats with antimicrobial options

Availability

The production line is now available in three configurations:

Pilot System (10-20 packs/min) for R&D

Mid-Scale (30-40 packs/min) with modular expansion

High-Volume (50-60 packs/min) full automation

For details, contact [email protected]

Press Package Includes:

✓ 3D animation of coating process

✓ Test reports comparing absorption rates

✓ Interviews with wound care specialists

Fully Automatic Band-Aid Produ

Fully Automatic Band-Aid Produ

Zowinda Launches Next-Gen Medi

Zowinda Launches Next-Gen Medi

Zowinda's 1500 PPM Bandage Mac

Zowinda's 1500 PPM Bandage Mac

Zowinda's 1500 PPM Bandage Mac

Zowinda's 1500 PPM Bandage Mac

Please contact us with your request

We are ready to answer your questions.